Extractor Fan Troubleshooter

Diagnose Your Extractor Fan Issue

Answer the questions below to identify why your fan stopped working and learn how to fix it.

Answer questions above to get your diagnosis

Safety First

Before working on your extractor fan:

- Always turn off power at the circuit breaker

- Never touch live wires

- Wear protective gloves and eye protection

- Call a professional if you're unsure about electrical work

Ever turned on your extractor fan and heard nothing but silence? It’s a frustrating moment - especially when you’re cooking and the smell of burnt food or steam just hangs in the air. You didn’t expect the fan to die, but it did. And now you’re left wondering: why has the extractor fan stopped working?

The Most Common Reasons Your Extractor Fan Isn’t Working

Most extractor fans fail for one of five simple reasons. None of them require a professional electrician - unless you’re uncomfortable with basic tools. The fix is often cheaper than replacing the whole unit.

- Blocked or dirty filters - Grease and dust build up over time. If the filter’s clogged, the fan can’t pull air through. It might hum, but it won’t spin.

- Faulty switch or wiring - The wall switch or the internal wiring can wear out. Especially in older homes, connections loosen or corrode.

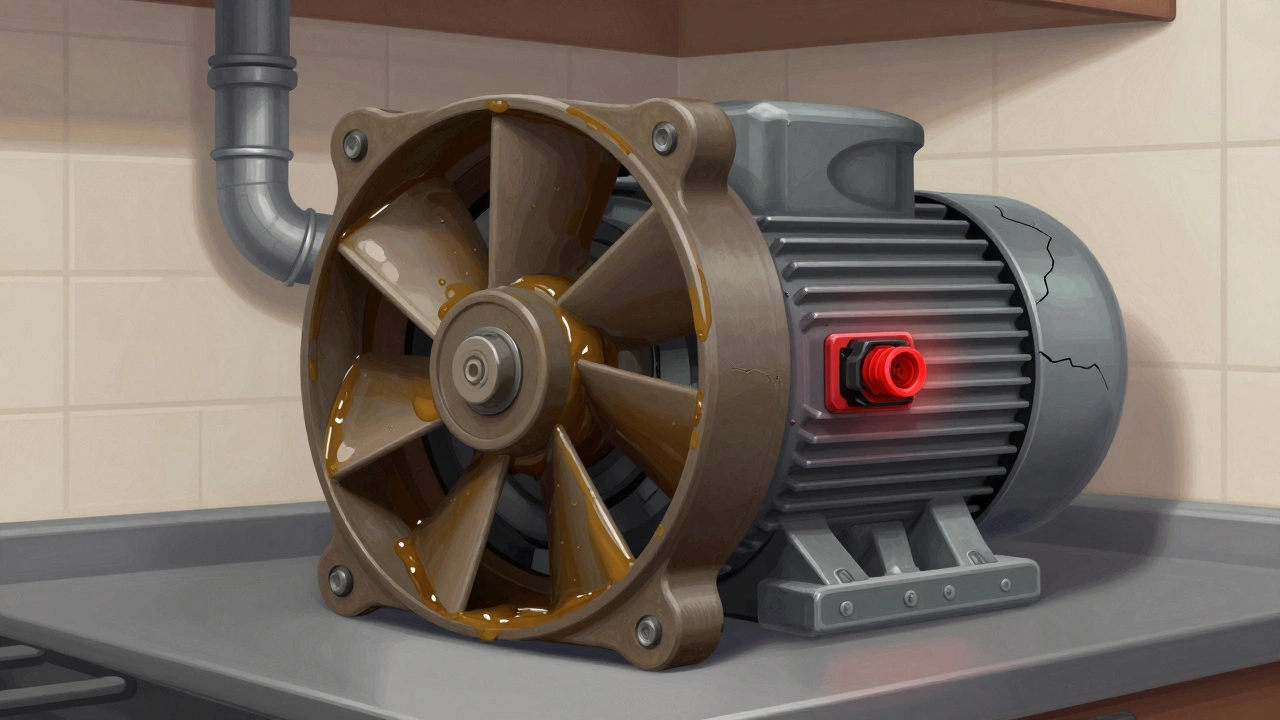

- Dead motor - The heart of the fan. Motors burn out from overheating, age, or constant use. You’ll usually hear a buzz but no rotation.

- Stuck or seized impeller - The blades get gummed up with grease. If they can’t turn, the motor won’t spin them.

- Tripped thermal cut-out - Many modern fans have a safety feature that shuts them off if they overheat. It resets after cooling down.

Step-by-Step: How to Diagnose the Problem

You don’t need to guess. Follow this order. It’s fast, safe, and saves you money.

- Check the power. Is the fan plugged in? (Some are hardwired, but still need a circuit breaker on.) Flip the breaker off and on again. If it trips again, there’s a short.

- Test the switch. Turn the fan on and off a few times. If it works intermittently, the switch is failing. You can bypass it temporarily by connecting the wires directly (only if you know what you’re doing).

- Remove the filter. Most extractor fans have a removable grease filter. Take it out. Clean it with hot soapy water. Let it dry completely. Try the fan again. If it works now, you found your culprit.

- Spin the blades manually. Turn off the power. Reach in (carefully) and try to spin the impeller by hand. If it’s stiff or won’t turn, grease has glued the blades in place. Use a soft brush and degreaser to clean around the shaft.

- Listen for a buzz. Turn the fan on. If you hear a humming noise but no spin, the motor is dead or the capacitor has failed. That’s the point where you might need a replacement part.

What to Do If the Motor Is Dead

If the fan hums but doesn’t spin, the motor or capacitor is likely gone. Before you replace the whole unit, check if you can replace just the motor. Many brands - like Zephyr, Falmec, or Extractas - sell replacement motors for under $50. You can find them online or at appliance parts stores.

Here’s what to look for:

- Match the voltage (usually 230V in New Zealand).

- Check the RPM (revolutions per minute). It should be within 10% of the original.

- Confirm the mounting style - some motors clip in, others screw down.

Replacing the motor takes about 20 minutes. You’ll need a screwdriver, pliers, and maybe a multimeter to test the old one. If you’re unsure, watch a YouTube video for your exact model. Most have clear step-by-step guides.

Why the Thermal Cut-Out Might Be the Real Culprit

Many newer extractor fans have a built-in thermal cut-out. It’s a safety device that turns the fan off if it gets too hot. This happens if the fan runs non-stop for hours, or if airflow is blocked.

Here’s how to tell if this is the issue:

- The fan worked fine yesterday.

- You’ve been cooking for hours - maybe a roast or deep fry.

- You turned it off, waited 30 minutes, and now it works again.

If this sounds familiar, you’re not broken. You’re just overworked. Clean the filters. Don’t run the fan 24/7. Let it rest. And make sure the ducting isn’t kinked or blocked. That’s often what causes overheating in the first place.

When to Call a Professional

You can fix most extractor fan problems yourself. But here’s when you should stop and call someone:

- The fan is hardwired and you’re not comfortable touching electrical wires.

- The circuit breaker trips every time you turn it on - that’s a sign of a serious short.

- You smell burning plastic or see smoke.

- The fan is part of a ducted system that vents through the roof. If the duct is blocked or damaged, it’s harder to fix alone.

In Dunedin, many older homes have extractor fans that haven’t been cleaned since they were installed. If yours is over 10 years old and has never been serviced, it’s worth having a technician check the ducting. Grease buildup in the duct can be a fire hazard.

How to Prevent This From Happening Again

Extractor fans don’t just die randomly. They die because they’re neglected.

Here’s how to keep yours running for years:

- Clean the filter every month. Especially if you fry, grill, or cook with oil.

- Wipe down the housing every 3 months. Use a damp cloth to remove grease buildup.

- Check the ducting once a year. Look for kinks, bird nests, or collapsed sections.

- Don’t leave it on all day. Turn it on 10 minutes before you start cooking, and leave it on 15 minutes after you finish.

- Upgrade to a fan with a timer. It turns itself off automatically. Saves energy and prevents overheating.

Most people think extractor fans are low-maintenance. They’re not. They’re the unsung heroes of your kitchen. Keep them clean, and they’ll keep your air clear.

What to Look for When Replacing Your Fan

If the fan is beyond repair, here’s what to consider before buying a new one:

- CFM rating - Look for at least 100 CFM (cubic feet per minute) for a standard kitchen. Larger kitchens need 150+.

- Noise level - Anything under 50 decibels is quiet. Above 60 is loud.

- Energy rating - Choose A+ or higher. Older fans use twice as much power.

- Smart features - Some now connect to apps or have humidity sensors. Useful, but not essential.

Brands like Elica, Broan, and Vent-A-Hood offer reliable models with easy access to replacement parts. Avoid the cheapest options - they’re often harder to repair and have shorter lifespans.

Why does my extractor fan make a buzzing noise but not spin?

A buzzing noise without spinning usually means the motor is getting power but can’t turn. This is often caused by a failed capacitor or a seized impeller. Try spinning the blades by hand. If they’re stuck, clean them. If they spin freely, the capacitor or motor needs replacing.

Can a clogged filter really stop the fan from working?

Yes. A heavily greased filter restricts airflow so much that the motor can’t pull air through. The fan might still hum, but it won’t spin effectively. Cleaning the filter fixes this in 90% of cases.

Is it safe to bypass the switch to test the fan?

Only if you’re experienced with electrical work. Bypassing the switch involves touching live wires. If you’re unsure, turn off the power at the breaker and use a multimeter to test continuity. Otherwise, call a technician.

Why does my extractor fan turn on by itself?

This usually happens if the fan has a humidity sensor that’s stuck or overly sensitive. It can also occur if the wiring is faulty and shorting out. Check the manual for sensor settings. If that doesn’t help, the control board may need replacing.

How often should I clean my extractor fan?

Clean the filter every month if you cook often. Wipe the housing every 3 months. Check the ducting once a year. In homes with heavy frying or grilling, clean the internal blades every 6 months. Neglect leads to grease fires.