Boilers are the unsung heroes of winter, tirelessly ensuring warm baths and cozy homes. But what happens when your boiler decides to take an unscheduled break? The question of tackling boiler repairs on your own comes with a mix of curiosity and caution.

In this guide, we'll unravel the mystery of boiler mechanics, explore common malfunctions you might face, and delve into safe fixing tips for handy homeowners. We'll also cover the crucial signs that signify it's time to wave the white flag and call in the professionals. Whether you’re a seasoned DIY enthusiast or new to home repairs, understanding these basics could save you both time and money.

- Understanding How Your Boiler Works

- Common Boiler Problems You Can Fix

- Safety Considerations in Boiler Repair

- When to Call a Professional

Understanding How Your Boiler Works

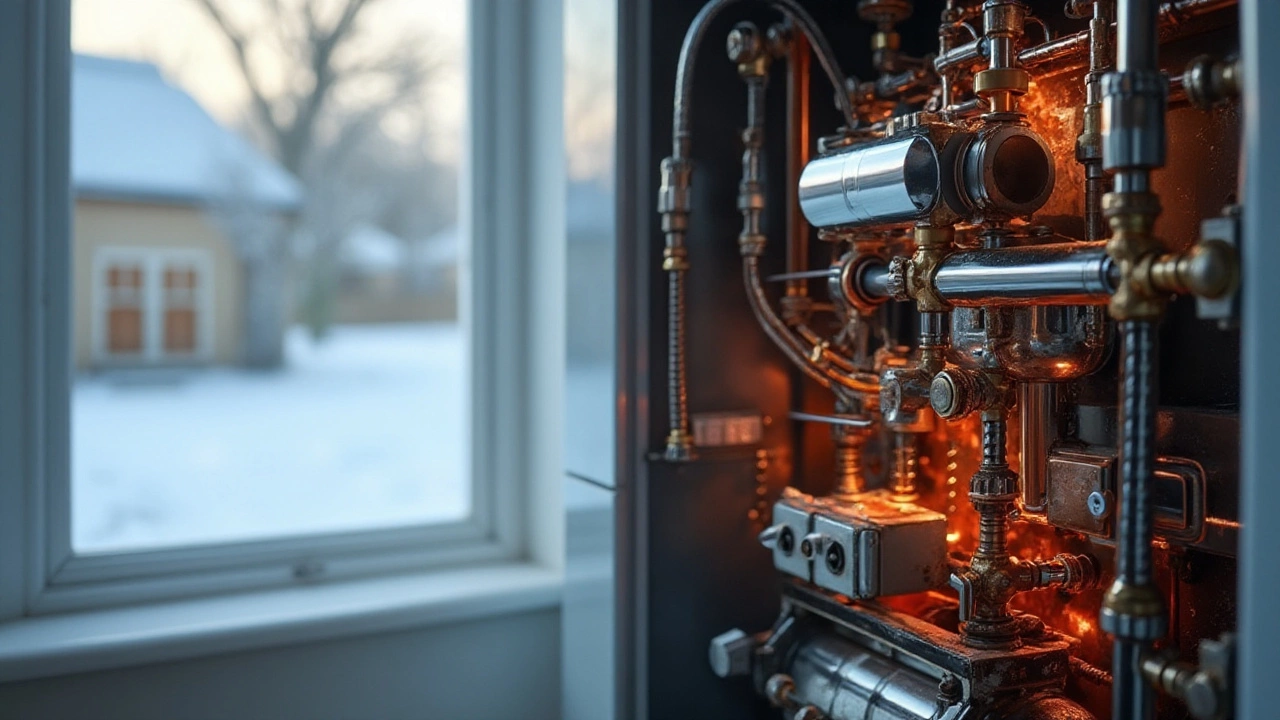

Let's dive into the world of boilers, those essential fixtures that seem unassuming until the frost sets in, and we desperately need them to spring into action. To successfully manage any boiler repair, first comes a solid grasp of the components and processes that drive it. At its core, a boiler operates on a simple principle: heat water to produce steam or hot water to distribute heat around your home. But within this simplicity lies a complex network of parts, each playing a crucial role in the energy conversion process.

The heart of the boiler system is the burner, where fuel mixes with air. This mix is ignited by a pilot light or an electric starter to create a controlled flame. The burner heats the water contained within the boiler's heat exchanger. As the water's temperature rises, it transforms into steam or remains as hot water and is cycled through pipes to radiators, convectors, or underfloor heating systems, delivering warmth to various spaces.

Efficiency in a boiler system is significantly affected by the different materials used in parts like the heat exchanger, generally made from copper or stainless steel. These metals excel at heat transfer, which is a process as crucial as the fuel-air mix. Did you know that condensing boilers, a particular type of high-efficiency models, can boast efficiency levels above 90% thanks to an additional heat exchanger that reclaims heat from exiting flue gases?

A crucial role is also played by the expansion tank, especially in hot water systems, which alleviates pressure by collecting and storing excess water due to thermal expansion. Meanwhile, the circulator pump propels the heated water throughout the system efficiently. Understanding these components helps you identify what might go amiss if your boiler suddenly stops doing its job.

According to the Energy Saving Trust, "Regular boilers can reach high efficiency levels of between 78-85% depending on maintenance, but condensing boilers take this up a notch thanks to their more advanced mechanisms."

But knowing the layout of your boiler is only half the story. For DIY boiler fix attempts, a certain level of familiarity with your specific model is invaluable. User manuals, albeit technical, often portray comprehensive diagrams that pinpoint the exact location of major parts, from the thermostat to the vent damper. If attempting a minor fix, aligning reality with these schematics ensures you're not shooting blindly into the heart of your home heating.

In many cases, the depth of understanding is exactly what empowers homeowners to perform basic maintenance or recognize when professional intervention is warranted. For instance, identifying a reluctant pilot light as a simple thermocouple issue rather than a fuel leak can prevent panic and unnecessary repair costs. So, the next time your boiler grumbles to a halt, arm yourself with this newfound knowledge to either spruce it up yourself or have a well-informed chat with the repair technician.

Common Boiler Problems You Can Fix

A boiler breakdown can throw anyone off balance, especially on a chilly day. The good news is that not every issue requires a trained professional; some boiler repair jobs can be tackled by you, the dedicated homeowner. It's all about knowing which problems are DIY-friendly.

One frequent culprit of boiler woes is a pilot light that just won’t stay lit. This can occur due to various reasons, like a draft or dirt accumulation in the pilot assembly. Safely clean the pilot light and relight it, making sure to follow your boiler's manual instructions carefully. Remember, each boiler type might have a slightly different mechanism. If the problem persists, it could be an indicator of a faulty thermocouple, requiring replacement—a task within reach for a confident DIYer. Just make sure to shut off the gas supply before you start tinkering.

Another common issue is low boiler pressure, which often causes heating inefficiencies. You may notice your home heating takes longer to warm-up, or perhaps it’s not as cozy as you're used to. Check the pressure gauge; if it’s below one bar, you’ll need to repressurize your system. Search for the filling loop, usually found beneath the boiler, and open the valves to let water fill into the system. Watch the gauge carefully and close the valves once it hits 1.5 bar. If pressure drops frequently, you might have a leak somewhere in your system, and it could be time to consult a professional.

According to the Energy Saving Trust, keeping your heating system well-maintained can save up to 10% annually on heating bills. So, even small fixes like these contribute significantly to energy efficiency.

Don’t overlook the painful sound of a ‘kettling’ boiler either—loud banging or whistling noises erupting out of your appliance like it’s a haunted kettle. This is often due to limescale buildup on the boiler’s heat exchanger caused by hard water, especially in regions susceptible to it. Descaling the boiler can prevent future noise disturbances and improve efficiency. Explore chemical descaler products suitable for your system, but handle with care and read all safety guidelines on the label. Regularly bleeding your radiators can also prevent similar blockages and maintain optimal circulation.

Finally, look at thermostat issues, which are often less a hardware malfunction and more a user-interface mishap. Make sure it's set to the desired temperature and timed properly. If the heating is refusing to come on, check to see if the thermostat has new batteries or if there's dust obstructing the sensors. A simple reset or a temporary bypass by substituting it with a controllable thermostat can sometimes fix the problem at a minimal cost.

Tackling these typical problems can help extend the life of your boiler while saving on repair costs. However, always prioritize safety and, when in doubt, it's wisest to reach out to a seasoned professional who can ensure your system runs smoothly without the risk of further issues.

Safety Considerations in Boiler Repair

Repairing a boiler is no small feat, especially when you're navigating through steaming pipes and ticking thermostats. Safety is the name of the game here, and it's crucial to treat this task with the respect it deserves. Boilers operate under high pressure and temperature, using potentially combustible fuels like gas or oil, making them inherently risky to tamper with if proper precautions are not observed.

Begin by powering down the system entirely; this includes switching off the boiler's electrical supply. Don't just rely on turning off the thermostat, as boilers often have discreet safety features that could still be live. Check for signs of leaks or corrosion around the fixtures, which could indicate deeper issues that require a professional hand. Remember, a DIY fix might seem tempting, but if the fix goes wrong, it can lead to more severe damage in the long term.

Essential Safety Gear

Dressing the part significantly enhances your safety game. Equip yourself with heavy-duty gloves, safety goggles, and if possible, a face mask designed to filter out airborne particles. This armor won't just protect you from the immediate risks but will also guard against long-term exposure to harmful substances that might be lingering around an old boiler. While you're at it, make sure your working environment is well-ventilated to avoid any risks of inhaling unwanted fumes.Regarding tools, stick to well-insulated handles to avoid any unexpected zaps. Although tempting to use whatever is in your toolbox, specialized tools for boiler repair are designed with the job's specific hazards in mind. These may include pipe wrenches, socket sets, and screwdrivers with insulated tips. Damage to the boiler that is caused by using the wrong tool could escalate what seemed like a manageable issue into something much less manageable.

Know Your Limits

Attempting a DIY boiler repair doesn’t mean you should go it alone. A simple pressure leak or a thermostat irregularity might be within your realm of fixing, but when the display panel flashes unfamiliar error codes, it’s time to step back. In fact, a startling statistic from HVACR Business shows that about 59% of boiler-related incidents are due to improper repairs.“Working on a boiler without understanding its systems and components is like driving blindfolded,” says John Harland, a renowned industry expert whose advice stresses knowing when to call in the pros.Such wisdom should not be overlooked as it literally can determine your safety and that of your home. Using expert technicians not only ensures the job is done accurately but often comes with warranties, giving you peace of mind against future hiccups.

When to Call a Professional

Tackling a DIY project always brings a sense of accomplishment, but there are times when calling in the experts is the wisest choice, especially when dealing with boiler repair. Though fixing minor issues might seem feasible, the complexity of modern boilers often demands professional intervention. Attempting to fix something beyond your expertise can yield costly consequences. If you're facing a boiler malfunction that involves electrical faults or gas leaks, it's crucial to call a professional right away. These issues can pose serious safety hazards, from carbon monoxide leaks to fire risks.

Boilers have sophisticated systems that require specialized knowledge to troubleshoot efficiently. If your boiler is showing error codes that you're unfamiliar with, it's time to reach out to someone who has the necessary diagnostic tools. Professionals not only understand these systems but have access to parts and resources that might be out of reach for the average homeowner. They also stay up-to-date with the latest safety regulations, ensuring that your repair job adheres to all necessary standards. An ineffective DIY repair could disrupt the efficiency of your home heating system, leading to higher energy bills or potentially more serious damage down the line.

Consider the age and warranty status of your boiler. If it's still under warranty, unauthorized repairs by yourself might void the cover, leaving you out of pocket for future issues. In such cases, ensuring repairs are documented and handled by certified professionals protects your investment. Moreover, if you encounter recurring problems despite multiple attempts at DIY fixes, it’s a telltale sign that something critical needs addressing, and expert evaluation is crucial.

While it might be tempting to save on costs initially, professional intervention can ultimately result in cost-saving. According to a HomeServe study, typical homeowners save up to 15% annually on their heating bills when using well-maintained boilers, an assurance professionals offer. A professional will provide peace of mind, securing not just the immediate malfunction but potentially detecting and addressing underlying problems.

As per Bob Vila, 'A professional repair ensures that your boiler operates safely and efficiently, which is paramount when considering the potential hazards involved.'Remember, when in doubt, it's always safer to err on the side of caution, ensuring the wellbeing of your household and the longevity of your boiler system.